NON METALLIC EXPANSION JOINT

NON METALLIC EXPANSION JOINT MANUFACTURERS

RB-FLEX flexible connectors are installed in the pipelines, ductworks and industrial apparatuses to compensate for inevitable expansion due to heat or misalignment as well as vibration as a result from mechanical movement. They are made from either fabric or Rubber or Combination of both. Renowned Manufacturers of NON METALLIC EXPANSION JOINT

Features

- Highly flexible and can absorb multidirectional movements and vibration.

- Light weight of compensator mean lighter duct support to lower cost.

- Good resistance to chemical attack.

- Resistance upto 1200°C

- Suitable for low pressure Gas/Air lines (2000 mm WC)

- Large moment capabilities in shorter face-to-face length

- Chemical gas resistant

- Very low spring rates

- Sound and vibration elimination

- Low system design cost as they can accommodate movements concurrently

- Lower replacement cost

Construction

Construction of joints vary from simple layer fabric for low temperature to complex insulated fabric for high temperature applications. Acid resistance fabric, insulation material and wire mesh are also used to give controlled movement. Outer membrane is generally made up of air tight special elastomer coated fabrics.

Special Fabric Joints

We also make use of the state of the art fabric in the world which has an advantage over the elastomer coated fabrics. Normal fabrics have unprotected fiberglass or coating PTFE which at best is 70% Amorphous and 30% Crystalline which consequently will crack and permit water and other chemical to destroy the fiberglass and thus the expansion joint. These Thermochemical fabric we offer is able to keep fiberglass dry and control its cannibalistic traits.

Features:

- Zero porosity nature

- High tensile and tear strength

- Mechanically rugged

- Excellent chemical resistant

- Long life hence low life cycle costing

- Best solution for chemical gas applications

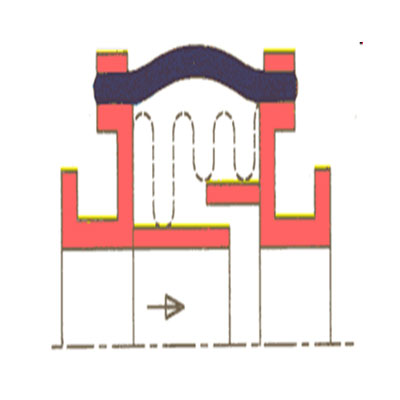

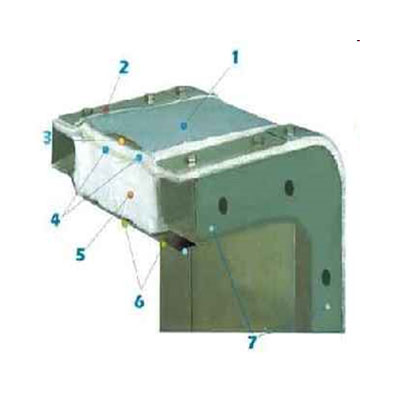

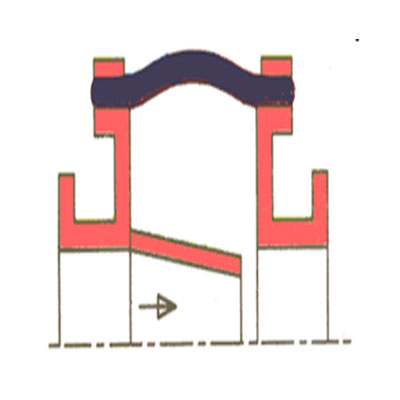

CROSS SECTION OF NON-METALLIC EXPANSION JOINT

1- COATED FABRIC

2- BACK-UP BAR

3- GAS SEALING LAYER

4- INSULATING FABRIC

5- BOLSTERS

6- INTERNAL SLEEVE

7- END FITTINGS

TYPES OF NON – METALLIC EXPANSION JOINT

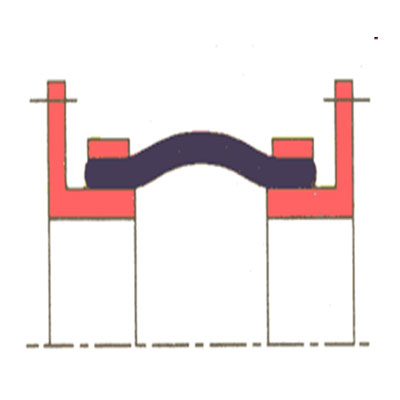

TYPE-1

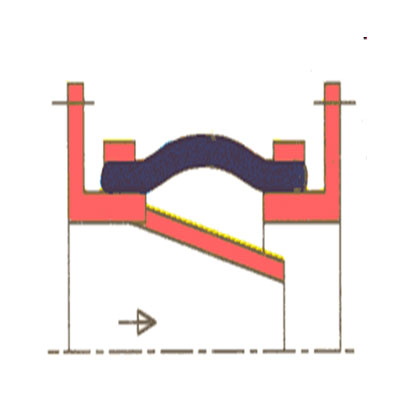

TYPE-2

TYPE-3