RUBBER EXPANSION JOINT

RUBBER EXPANSION JOINT MANUFACTURER

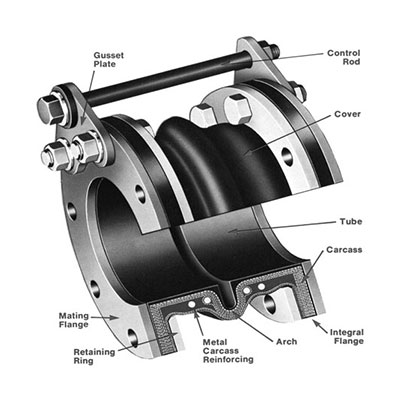

RB-FLEX rubber expansion joint manufacturer is a flexible connector hand moulded with fabrics & metallic reinforcements. They generally have integral Flanges (hence no need of gasket) with necessary control unit assembly.

Rubber expansion joints have been specified and used for many years by consulting engineers, mechanical contractors, plant engineers and turn-key construction firms.

These are used to absorb and protect the system from noise, vibration, thermal expansion, stress, movement and protect against start up surge force.

These are suited for high pressure upto 30 Bar and temperature upto 120 degree centigrade (with special construction the same can be increased). These are made from high tensile rubber with Rayon / Nylon reinforcement and metal rings for various duties.

ADVANTAGE OF RB-FLEX RUBBER EXPANSION JOINT

- Reduce vibrations

- Dampen sound transmission

- Compensate axial, lateral, torsional and angular movements

- To relieve system strain due to thermal change, load stress, pumping surges, wear and settling

- Eliminate electrolysis

- Freedom from Corrosion

- High Resistance to Shock

FEATURES OF RB-FLEX RUBBER EXPANSION JOINTS

| SIZE: | 25 NB UPTO 2400 NB IN CIRCULAR / RECTANGULAR ALSO AVAILABLE |

| D/PRESSURE: | FULL VACUUM TO DESIGN 30 BAR |

| TEMPERATURE: | -50 DEG C to 120 DEG C |

| MATERIAL: | EPDM / NEOPRENE / BUTYL / OTHER RUBBERS |

| DESIGN CODE: | FSA (FLUID SEALING ASSOCIATION STANDARDS) |

| USE IN: | PUMPS, TURBINES, BALLAST LINE, VACUUM LINE, HVAC etc. |